Rebar Couplers

Tooltech Engineering is a downstream rebar coupler manufacturer aimed at easing and simplifying construction practices around the globe. It caters to every kind of reinforcement requirement and redefines the concepts of time and inventory management at site. Tooltech Engineering has been manufacturing Rebar couplers as per customers need from year 2014 and has customers all over the world. We make couplers according to the customers need and specifications, along with providing all the necessary certificates for quality and strength.

Current Practises In Lapping

Lapping of rebar's is the most common method of reinforcing bar joints but is not always the most appropriate. The process includes overlapping two bars for a certain lap length and tying them together with the help of binding wire. As a result the overlapped length of rebar's is wasted and it leads to greater congestion within the concrete because of the increased amount of rebar used. Also, the task of holding and tying the rebar's together is labor intensive and time consuming.

Lapping of rebar's is the most common method of reinforcing bar joints but is not always the most appropriate. The process includes overlapping two bars for a certain lap length and tying them together with the help of binding wire. As a result the overlapped length of rebar's is wasted and it leads to greater congestion within the concrete because of the increased amount of rebar used. Also, the task of holding and tying the rebar's together is labor intensive and time consuming.

SOLVING THE PROBLEMS WITH COUPLERS!

Tooltech Engineering makes Couplers which are hollow mechanical members used to join reinforcement bars. These are threaded on the inside and are fixed on the two rebar's which are to be joined to form a mechanical joint. Our couplers are designed in a manner so that their properties are at par with international standards.

1. The Rebar's to be joined are supplied with parallel threads to cut onto the ends to be joined.

2. Prior to thread cutting, the ends are cold forged to the required length and diameter to ensure correctness of fit

MAKE THE CONNECTION WITH A WORLD OF BENEFITS:

• Reduced Rebar Usage: Lap Length of the order of 40-50x Diameter, which cannot add any value structurally, are avoided and usage of binding wires and difficult handling is avoided.

• Reduced Congestion: Smooth flow of concrete during pouring and hence, sound structural integrity. Ideal steel-cement ration ensures optimum steel in the structural member cross section.

• High Structural Integrity: Mechanical joints are less dependent on the concrete for load transfer.

• Faster Construction: Reduced handling and faster assembly ensures quicker installations.

• Easier Future Extensions: It can be installed as provisions for future extensions. A coupler eliminates the undesired look of extended Rebar's and the huge amount of concrete breaking required during extension.

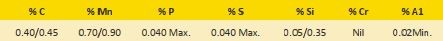

CHEMICAL COMPOSITIONS OF COUPLERS:

Our Couplers are in compliance to En8D grade and hence chemistry is as per its specifications.

APPLICATION AREAS:

‣ Column-lap replacement.

‣ Raft Foundations.

‣ Wall to slab connection.

‣ Beam to column connection.

‣ Precast elements.

‣ Future extensions/additions.

WORLD CLASS STANDARDS:

All couplers comply to international Specifications such as EN 1992 and BS 8110.

※ Parent Material Test Certificate.

※ To ensure quality of the parent material being used.

※ Physical Dimension Test Certificate.

※ To ensure manufacture as per our design.

※ Sample Pull Test from the lot.

※ To ensure physical properties of the coupler joint.